What is Reverse Logistics?

Reverse logistics is the process of planning and controlling the flow of goods from the end consumer back to the point of origin – typically the retailer, or even the original manufacturer. Having a well-thought-out, well-implemented process for handling the reverse flow of goods (returned items) is a necessity for today’s shippers. Especially, when you consider that Americans returned $743 billion in goods, about 14.5 percent of all purchases, in 2023, according to the National Retail Federation.

So what can you do to improve your reverse logistics process? These tips will get you off to a good start.

1. Create a “Returns Area” and Sort Shipments as Soon as They Come In

Building a solid reverse logistics process starts in the warehouse. We suggest keeping returns contained to one area, and sorting them into four categories – restock, discard, return to supplier, and priority – as soon as they come in. This keeps your warehouse organized, and ensures that items are routed correctly from the get-go.

2. Restock Items Quickly

Monitor your returns marked as “priority” and “restock” regularly and get them scanned and stocked back onto your shelves as quickly as you can. Doing so ensures your inventory and ordering systems are up to date, and that products are available for resale sooner.

3. Consider Repairing, Refurbishing, and Reselling Damaged Items

Reverse logistics is about mitigating your losses, and reselling refurbished or “as is” items is another way to recoup what would otherwise be lost money. These items can be listed for lower prices and may appeal to customers who can’t or won’t pay full price for your merchandise.

4. State Your Returns Policy Clearly

After you’ve implemented these reverse logistics strategies in your warehouse, it’s time to focus on making returns easy for your customers. This starts with stating your returns policy clearly so potential buyers know what to expect. In retail, and especially in online retail, many consumers will investigate companies’ return policies before pulling the trigger on an item. You want to assure them that their returns will be handled and credited back to their accounts quickly. Showing them how the returns process works with a step-by-step illustration or guide will also help customers understand the process, minimize delays, and improve the odds of returned items reaching you in good condition.

5. Pack Return Labels with Your Shipments

Packing return labels with every shipment is another step in reverse logistics that can make returns easy on your customers. If you can manage, make your labels “scan-based labels” also known as “pay on use labels” to score major points with consumers. Paying for return shipping can be expensive, but the goodwill you build by improving the customer experience is likely to pay for itself quickly. If you’re worried about the extra costs, implement paid return labels as a pilot program for a defined period, then perform a cost/benefit analysis to determine its validity for your operation.

6. Invest in Durable Packaging and Ensure that Shipments are Easy to Open

If you plan on having customers send returns back in the original boxes or envelopes, make sure those materials are durable enough to handle a two-way trip. Cheap packaging materials, or packages that are difficult to open get damaged easier, which means your merchandise is also more likely to get damaged during the return trip. Besides, there aren’t many things that frustrate a customer more than having to buy their own packaging just to return something they no longer want.

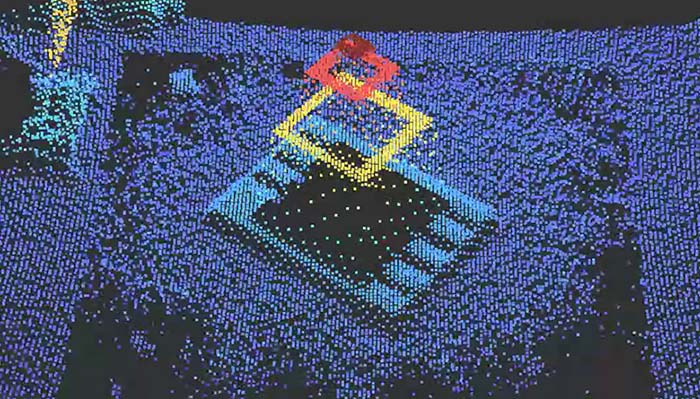

If you’re a reverse logistics company, learn more about why you should choose FreightSnap for your dimensioning process here.

For more articles like this, subscribe to our newsletter!

Was this article helpful?

Michael Eichenberg is the co-founder and CEO of FreightSnap, allowing the supply chain, logistics, manufacturing, distribution and transportation industries to measure, weigh, photograph and ID pallets and parcels in just seconds. Learn more and share your ideas on Facebook and LinkedIn.g