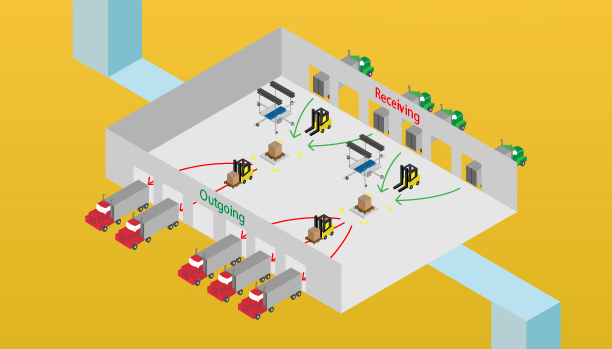

In the rapid world of logistics and freight management, identifying leaders in innovation is crucial. Enter FreightSnap, your solution to warehouse automation and optimization. The FreightSnap Image Station, a groundbreaking development in automated freight documentation, is redefining the game for shippers and carriers.

Join us on an exciting journey as we explore a day in the life of “John,” a hypothetical warehouse manager who symbolizes many in the industry. Through John’s eyes, we’ll explore how the integration of warehouse management software and the Image Station has transformed his operations into a model of efficiency, accuracy, and productivity.

Warehouse Optimization: Breaking Free from Outdated Methods

John’s warehouse was mired in age-old manual processes, similar to countless others. Recording essential freight details like Shipment IDs and weight manually was not only draining but also error-ridden.

The Labor-Intensive Battle of Documentation:

Picture a late Friday evening in John’s bustling warehouse, and feel the urgency of a substantial shipment pending before the weekend. John, already fatigued from a strenuous week, found himself bogged down in physical documentation, errors creeping in, and the workflow waning.

The countless hours consumed by this monotonous process slowed the workflow to a near halt. John knew change was essential. He sought a solution to revolutionize this tedious task, enhancing efficiency.

The High Risk of Errors:

In a manual environment, John’s warehouse was a breeding ground for mistakes. From incorrect entries to simple transcription errors, John recognized the vulnerabilities. These small but significant errors could escalate into severe problems.

John’s solution? The FreightSnap Image Station, a beacon of warehouse automation technology. It offered a way to move past the manual grind that stifled his warehouse. With this cutting-edge technology, John could envision a future where efficiency and accuracy were paramount.

The Transformation: FreightSnap Image Station – An Era of Warehouse Efficiency

With the Image Station, John’s warehouse was reborn. Its state-of-the-art cameras allowed for quick capturing of crucial freight data, in stark contrast to the tedious manual hours once needed.

Let’s dive into how John maximized this technology:

Inventory Management:

Transitioning from manual audits, the Image Station automated processes, offering real-time insights.

Error Reduction:

Automated documentation minimized shipping discrepancies, enhancing customer satisfaction.

Peak Season Flexibility:

Warehouse automation ensured processing large orders without sacrificing precision, even during peak seasons.

In these ways, the Image Station revolutionized John’s operations.

Warehouse Optimization – Welcome to a New Dawn

Today, John’s warehouse is unrecognizable from its manual past. FreightSnap’s Image Station has turned his operations into a streamlined hub of efficiency. It serves as an example to warehouses worldwide, offering opportunities for unparalleled optimization.

Automated freight documentation is no longer a dream but a reality, and the FreightSnap Image Station is leading the charge. Its scalable solutions and fast ROI could be the key to unlocking your warehouse’s potential.

Are you ready to revolutionize your warehouse management? Explore the potential of the FreightSnap Image Station. Contact us for a tailor-made integration plan at [email protected] today! Let’s bring your warehouse into the future, together.

For more articles like this, subscribe to our newsletter!

Was this article helpful?