The rapid growth of ecommerce is re-shaping the supply chain. Today, manufacturers, distribution and fulfillment centers, and transportation companies are all scrambling to keep up with rising shipment volumes and ever-shrinking delivery windows.

How are they doing it? Well, in part, by investing in automated warehouse solutions designed to improve productivity, reduce waste, and increase profitability. In fact, according to Logistics Management’s 2018 Warehouse/Distribution Center Equipment Survey, 42% of respondents expected to proceed with their planned investments for 2018 – a four year high for that response.

So, what kinds of equipment should companies consider when they want to improve warehouse operations? Here are 4 tools that deserve a closer look.

Cartonization Software

Companies that rely on guesswork to determine the correct box size for their goods end up wasting a lot of money on shipping and material costs each year. Cartonization programs automatically calculate the optimal container size needed to ship goods safely and securely, and can significantly decrease the time needed to pick and pack shipments, whether by hand or as part of an automated process.

Automated Parcel and Pallet Dimensioners

In a world where parcel and LTL carriers are increasingly charging on dimensional weight, it’s become essential for shippers to collect accurate dimensions on every shipment to receive the lowest rates.

Automated dimensioners allow shippers to capture accurate, legal-for-trade measurements of their large and small freight in just a few seconds. This saves them loads of time and money while also eliminating costly mistakes that crop up when measurements are taken or transposed incorrectly by hand.

Additionally, some enterprising operations are also using dimensioners to measure goods before they ever hit the shelves to maximize valuable storage space and deliver up-to-date dimensions to their carton optimization programs.

Bottom line – dimensioners ensure accurate rate quotes, fewer errors, more efficient use of storage space, and encourage better packaging practices, which all lead to major savings.

Automated Boxing and Packaging Machines

Automated boxing solutions continue our theme of waste and cost reduction when it comes to shipping. Companies like Packsize, Box On Demand, and others offer systems that build custom boxes as needed.

Instead of a traditional shipping process where shippers are forced manage a large inventory of boxes for different sized goods, automated boxing machines build boxes that are “made-to-order” at the exact dimensions needed to safely and economically ship merchandise.

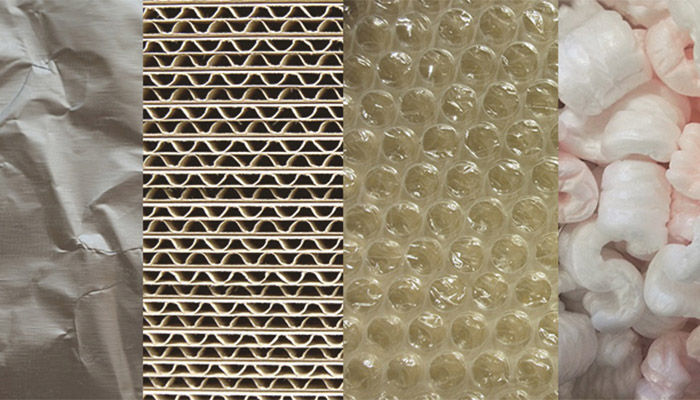

This reduces the amount of corrugated material, padding, and filler used on each shipment, and can lead to huge savings in material and shipping costs.

As a bonus, these systems also promote greener operations, which are better for the environment, and something many consumers appreciate.

Automated Label Printer/Application Equipment

Label printing and application machines automate the routine task of manually applying shipping labels and packing slips by hand. They can operate at 5 to 10 times the speed of a manual process, and free employees up for more valuable work inside the warehouse. When paired with in-line dimensioning systems, cartonization software and/or box-making equipment, throughput of parcel and palletized shipments can increase dramatically.

Additionally, these systems, as well as the others we’ve mentioned, can be integrated with WMS systems to ensure that the lowest shipping rates are found and applied your freight in a quick, efficient, and error-free process.

For more articles like this, subscribe to our newsletter!

Was this article helpful?

Michael Eichenberg is the co-founder and CEO of FreightSnap, allowing the supply chain, logistics, manufacturing, distribution and transportation industries to measure, weigh, photograph and ID pallets and parcels in just seconds. Learn more and share your ideas on Facebook and LinkedIn.