Measuring, weighing and photographing palletized freight by hand can be a time-consuming process that leaves room for measurement and transposition errors. The current generation of static pallet dimensioners have automated this process, allowing companies to capture this information and share it with their resource management systems in a fraction of the time, all without error.

That said, high-volume carriers and shippers are pushing the limits of these static dimensioners, and demand for even faster dimensioning equipment is growing. To meet it, dimensioning companies have explored a number of solutions, including in-motion dimensioning systems, which allow users to measure freight while it’s moving through the measurement zone. However, these in-motion systems are limited in regards to the type of freight that can be measured in motion (only cuboidal), the speed at which freight can move beneath the dimensioner (under 3 mph), and the accuracy of measurements (± 1.0” for in-motion vs ± 0.50” for static devices). In-motion dimensioners are also larger than most static devices, making them less appealing where warehouse space is limited. They can also require floor sensors, which are more likely to be damaged by forklifts and other floor traffic.

FreightSnap’s New, Hybrid Solution

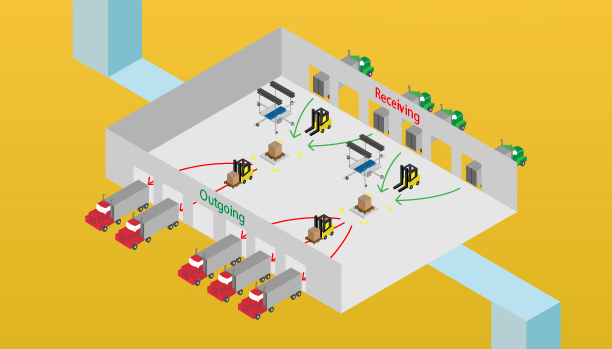

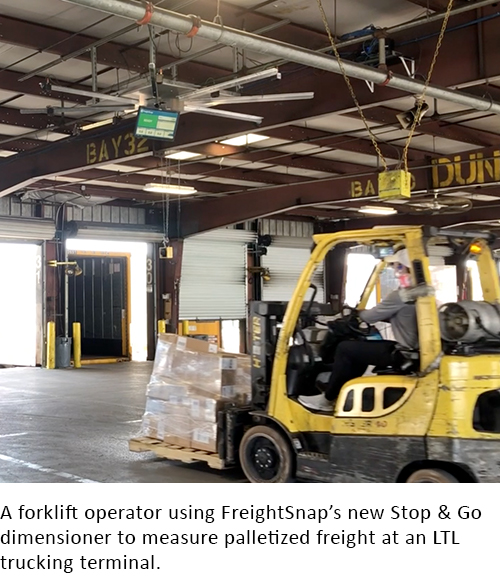

Given the current limitations of full in-motion dimensioning systems and static devices, FreightSnap has engineered a new solution, which they believe will meet the expectations of high-volume freight movers. They call it Stop & Go, and as the name implies, it will allow users to stop briefly beneath the dimensioner (without disengaging from the pallet) and still obtain accurate measurements of their freight.

With current static systems, forklift operators must drop their freight under the dimensioner, disengage from the pallet, and exit the measurement zone before initiating a scan – a process which can take between 7 and 15 seconds per pallet, depending on the driver. The Stop & Go system allows operators to simply pause beneath the unit, lower their freight to the ground, initiate the dimensioner, then pick up their freight and move on – a process which takes just 3 to 6 seconds while reducing the maneuverability required by the driver.

Watch a short demo of FreightSnap’s Stop & Go dimensioner here.

Other Benefits to Stop & Go Pallet Dimensioning

In addition to simplifying and streamlining the dimensioning process, Stop & Go as it’s envisioned by FreightSnap has a few other draws, including:

Maintaining Accuracy Standards

FreightSnap plans to have its Stop & Go solution certified to the current ± 0.50” standard preferred by most companies.

Easy and Affordable to Upgrade

The Stop & Go dimensioner is built on the same chassis as FreightSnap’s current static pallet dimensioner, the FS 5000, which will make it easy to upgrade. FS 5000 users will simply purchase an “upgrade kit,” which will include extra 3D sensors loaded with the software needed for Stop & Go capabilities.

Improved Maximum Measurement Range

With its additional sensors, the Stop & Go dimensioner will be able to measure freight up to 168″ long x 120” wide x 102” tall, whereas FreightSnap’s current device is certified to measure freight up to 120″ x 120″ x 96″.

When will Stop & Go be Available?

FreightSnap is in the final stages of product development with their Stop & Go dimensioner and will be pursuing NTEP certification later in 2019. If the schedule holds, FreightSnap expects the new units to be available in late 2019 or early 2020.

For more articles like this, subscribe to our newsletter!

Was this article helpful?