You have the latest pallet wrapping equipment. You take great care to correctly package your freight, wrap it, and prepare it for shipment. You’ve even purchased the right size of pallets to avoid needless shipping charges due to unused space.

Then what happens? The dreaded reclassification from the carrier.

What happened?

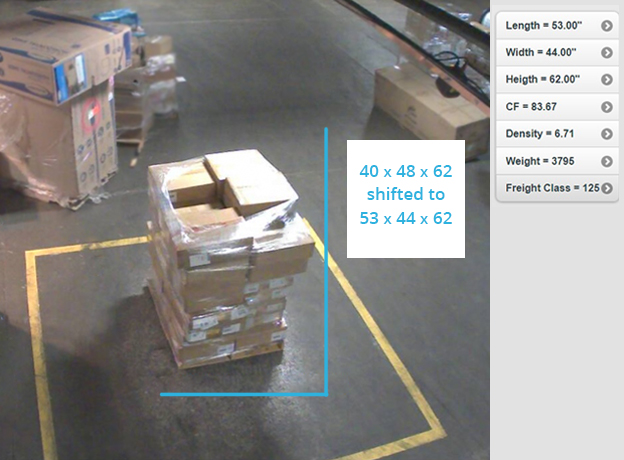

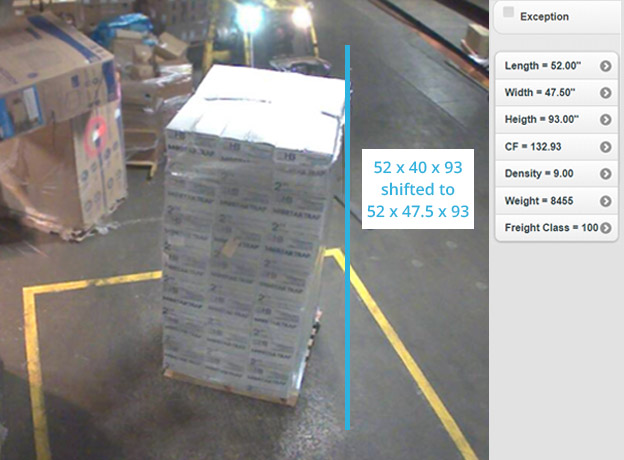

Your shipment began its journey neat and tidy at your plant. Soon, it was picked up by the carrier, forklifted to a dimensioner, and after being jostled around, it looks larger than when it left your warehouse.

Carrier docks are busy places. Workers are under tight deadlines to unload trailers, process pallets through dimensioning equipment, and stage freight near the correct trailer. Sometimes freight is simply cross-docked and moved from one terminal to another where it’s handled multiple times before being dimensioned by the carrier. Through no fault of the carrier, the freight shifts, resulting in additional fees and incorrect documentation.

Cover your assets

Having your own documentation process is the best countermeasure for incorrect accessorial charges. Without your own records, you’re at the mercy of the carrier’s information, which might not be a true reflection of your shipment. Using a high-quality dimensioner is a fast and productive way to measure, photograph and collect your data to present to the carriers. Image records can also optimize quality control and organize order information through your warehouse management system. It’s almost impossible for shipping managers to review every pallet before it’s transported but having easy access to freight photos is an excellent substitute. Good documentation is the perfect countermeasure to unexpected freight charges and penalties due to unexpected freight movement.

The ideal shipment

The image below is an example of the information a shipper receives from a FreightSnap dimensioner. This process saves time by collecting the image, weight and dimensions simultaneously. With the FreightSnap cloud system, you can access this information to counter reweighs and reclassifications. Notice the scale is under the dimensioner. Scale devices integrate electronically with FreightSnap Dimensioning Systems.

Actual dimensions, weight and density are provided in real-time to the shippers’ rating system to get competitive and accurate bids. Industry best practices save shippers real dollars in the form of better overall rates, fewer unrecoverable reweighs, reclassifications and damage claims.

How does your shipping process measure up?

The shipping process is fast-paced, and there’s no guarantee your freight will remain compact throughout its journey. Documenting your freight before it leaves your dock is the best way to dispute additional shipping fees and save your bottom line. Save money, increase productivity and improve accuracy by automating your entire measuring and weighing process.

For more articles like this, subscribe to our newsletter!

Was this article helpful?

Michael Eichenberg is the co-founder and CEO of FreightSnap, allowing the supply chain, logistics, manufacturing, distribution and transportation industries to measure, weigh, photograph and ID pallets and parcels in just seconds. Learn more and share your ideas on Facebook and LinkedIn.