The Importance of Dimensioning Systems

In the world of shipping, unexpected costs can quickly spiral out of control, putting a significant dent in your profits. One common source of these unforeseen charges is freight reclassification. But what if there was a way to drastically reduce these costs and improve your bottom line? Enter the pallet dimensioner, a revolutionary tool that has the potential to save shippers hundreds of thousands of dollars each year in chargebacks alone.

The Rising Importance of Freight Auditing

As the shipping industry evolves, carriers are increasingly relying on auditing processes to verify the dimensions and weights of the freight they handle. On average, carriers audit 40% or more of the freight that comes through their doors. This means if you’re shipping hundreds of pallets daily, a sizable portion is being scrutinized using a dimensioning system. Moreover, carriers are reaching to audit as much as 80% of the incoming freight by utilizing more efficient technologies.

The Hidden Costs of Freight Reclassification

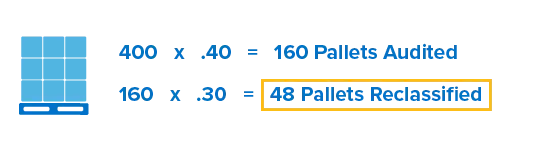

Freight reclassification occurs when a carrier’s dimensioning system detects inaccuracies in declared measurements and dimensional weights. Roughly, 25-30% of audited freight gets reclassified. So, if you’re shipping 400 pallets a day, this could mean around 48 pallets being reclassified, leading to avoidable chargebacks.

Curtailing Chargebacks with an Accurate Dimensioning System

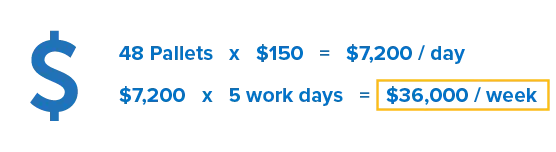

Carriers typically impose chargebacks ranging from $50 to $250 per reclassified pallet. Using a penalty of $150 per reclassified pallet as an example, you could be losing up to $7,200 a day to unnecessary chargebacks. Over the span of a typical work week, this could balloon to a whopping $36,000 in carrier chargebacks. Just imagine the savings you could accrue with an accurate dimensioning system in place.

The High Price of Manual Measurement Processes

When you look at the cumulative cost over a year, the figures can be staggering. Reliance on manual measurement processes could cost your business hundreds of thousands a year – significant capital that could be better utilized to drive growth and innovation in other areas of your business. And this doesn’t even include the savings in labor.

*Up to 60 seconds manual measurement per pallet vs. 15 seconds to drop, trigger and pick up freight!

Revolutionizing Shipping Operations with a Pallet Dimensioning System

If the figures mentioned above resonate with your shipping operations, it’s high time you considered investing in a pallet dimensioning system. Such an investment could offer a return on investment (ROI) in just two to three weeks. And if you ship more than this, you’ll see that ROI even faster. Embracing a pallet dimensioner is not an expense, but a strategic investment in the future of your company.

At FreightSnap, we’re committed to helping shippers optimize their operations and protect their bottom line. Our advanced dimensioning systems are designed to prevent costly reclassifications and chargebacks, potentially saving you a significant amount of money in the long run. Make this critical investment today, and you’ll start reaping the benefits almost immediately.

For more information on how FreightSnap’s pallet and package dimensioning systems can transform your operations and bolster your bottom line, don’t hesitate to reach out to us today at sales@freightsnap.com.

For more articles like this, subscribe to our newsletter!

Was this article helpful?

Learn more and share your ideas on Facebook and LinkedIn.