The Importance of Freight Class

As the debate between density-based freight pricing and the class-based system rages on, it’s no secret that less-than-truckload carriers in the United States are steadily moving toward dimensional weight pricing regardless of shipper’s qualms – after all, density based pricing is already the standard in most parts of the world. That said, the shift is proving to be gradual as shippers remain cautious of any changes made to the class-based pricing structure that’s been in place for decades. With that in mind, we’ve put together a list of four short and simple steps that will help you calculate the class of your freight, and in turn, more accurately predict the cost to ship your goods through an LTL service.

Step 1: Weigh Your Freight

First, use an NTEP-certified floor or forklift scale to weigh your freight. You’ll need the weight to calculate your shipment’s density, which comes later.

Step 2: Measure Carefully

If you’re using a tape, remember to measure to the extremes. If your freight is sitting on a pallet, use the pallet’s length and width as they should be the widest and longest dimensions of your shipment.

NOTE: If possible, avoid letting your freight overhang the edges of your pallet. Overhanging freight can lead to pricing adjustments down the road. Not only that, but overhanging freight is typically less secure and more likely to incur damage during transit.

If you’re not using pallets to ship your freight, or if there’s no way to avoid overhang, simply measure to the widest longest and highest points of your shipment. Be sure to include any protrusions or packaging that sticks out.

Step 3: Calculate the Density

Density is a key component in the classification of your freight, but before you can calculate the density of your shipment, you’ll need to determine the cubic feet. To do this, multiply your freight’s length, width and height together, then divide that number by 1,728, as there are 1,728 cubic inches in a cubic foot.

To calculate density, just divide the weight of your shipment by the total cubic feet. For example, if your shipment weighed 575 pounds and came out to 55.55 cubic feet, the equation would look like this: 575/55.55 = 10.35.

Step 4: Choose the Right Freight Class

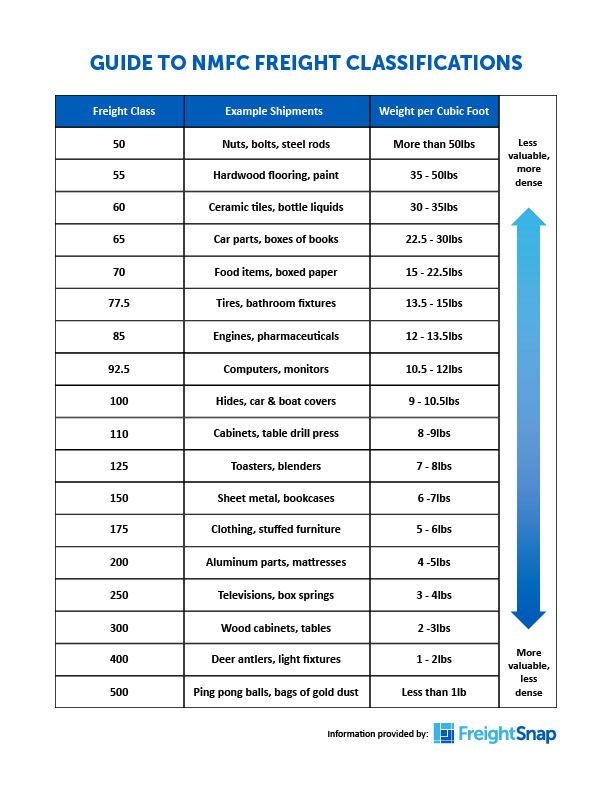

Here’s where it gets a little more complicated. If you’re not familiar with the National Motor Freight Traffic Association’s (NMFTA) class-based grading system, you can read more about it here. But in summary, the system groups commodities into 18 classes from 50 to 500, with lower classes costing less to ship. Classes are determined primarily by the shipment’s weight per cubic foot (density), but also factor in four other characteristics: value, stow-ability, handling and liability. In general, items will be classed higher despite their density if they are more valuable, more difficult to stow, harder to handle or have greater liability (higher chance of being damaged or stolen).

Without the NMFC Classification Book on hand, it’s impossible to be 100% sure of your freight’s final class as determined by your carrier. However, density alone will typically get you close. We’ve also provided a helpful Freight Class Guide below, which lists examples of freight classes for some commonly shipped items.

To get a free copy of the Freight Class Guide in PDF format, just enter your name and email, and we’ll send you a downloadable copy.

Final Thoughts

Freight classes, for better or worse, are here to stay for the time being as LTL carriers continue their gradual transition toward dimensional weight pricing. For shippers, this means it’s still important to know how the class system works. For greater accuracy and speed in calculating freight classes, shippers may also look at employing the same certified freight dimensioning equipment used by carriers to automatically measure, weigh and class the freight coming through their docks.

For more articles like this, subscribe to our newsletter!

Was this article helpful?

Michael Eichenberg is the co-founder and CEO of FreightSnap, allowing the supply chain, logistics, manufacturing, distribution and transportation industries to measure, weigh, photograph and ID pallets and parcels in just seconds. Learn more and share your ideas on Facebook and LinkedIn.