In a warehouse or distribution center, slotting refers to the storage and organization of goods in a manner that maximizes storage space and improves the efficiency of picking and pulling operations. It might sound complicated, but it’s actually something we all do every day, whether we know it or not.

Consider your pantry as an example. The bread, cereal and other items you want quick access to are probably located front and center where they’re easy to grab, while the evaporated milk, canned beets and items you don’t use often are tucked somewhere in the back. You’ve organized your pantry so the things you use most are readily available, while the things you only use occasionally take more effort to get to. This principle is the same in the warehouse, although there are a few more things to consider, which we’ll explore in the following sections.

First Thing’s First – Rank Items by Pick Frequency

Just like in the pantry example, you want the items you touch the most to be stored in the most easily accessible areas nearest their final destination, a loading dock or pallet wrapping station for example.

The easiest way to ensure this happens, is to rank each item in your warehouse by pick frequency. Some warehouse management systems (WMS) can do this for you. If you don’t have a WMS, your sales or shipping records can also tell you which items were picked the most.

Remember, you want to rank items by the total number of times they were picked, NOT the quantity picked. Ranking by quantity could result in one pick of 500 units getting better placement than say 400 picks of another.

If you only do one thing to improve your slotting system, make it this. You’ll be surprised at the new level of efficiency you can achieve.

Rank Storage Locations

Before you jump to place the most frequently picked items in the best locations, you’ll need to define what the best locations are. Think about the distance your picker will have to travel to get to the location (the shorter the better), then think about how easy it will be to pick the item when they get there. In some cases, putting an item a little farther away, but on a bottom row might ultimately save more time than putting it closer, but on the top shelf.

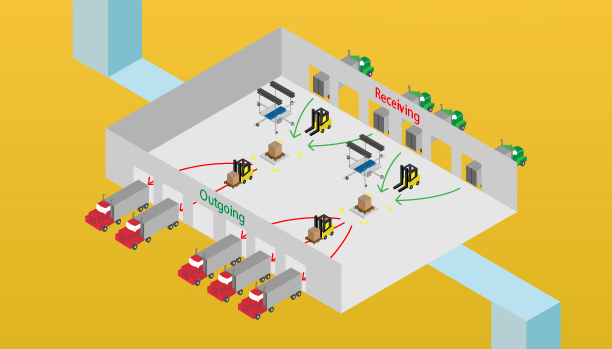

You’ll also want to consider the style of picking that goes on in your warehouse. Are pickers going to one location to pick one order, then taking that order straight to the dock (the case in pallet picking operations), or are they picking multiple items from multiple locations to build out an order?

If picking by the pallet, you can simply rank your locations based on the distance traveled from a fixed starting point. If picking multiple items from multiple locations, you’ll want to store items in a way that produces the shortest possible path from point A to B to C, then back. It can also be helpful to place items that are frequently picked together as part of the same order closer to each other.

Match Items to Locations and Consider Size

Now that you have your items and locations ranked, all you have to do is match the most frequently picked items to highest ranked locations. Obviously, the size of each item and the number of pieces that need to be stored at each location should be considered. Remember that larger items will need larger slots, thus taking up larger pick faces and requiring your pickers to travel greater distances to get to the next slot.

For example, let’s say that one of your larger items gets picked 350 times every six months and takes up a pick face of 10 feet by 10 feet. Now let’s say that three smaller items each get picked 125 times every six months, but will fit in the same 10-foot by 10-foot area. In this case, it would make more sense to slot the three smaller items in the better location because you’re ultimately going to get more total picks out of the slot.

Do I Really Need to Know the Size of Each Item in My Warehouse?

Ideally, yes. While it might seem impractical or even impossible to measure each kind of item currently stored in your warehouse (not to mention any new items you get in), automatic dimensioning equipment can make it a lot easier than you think. Today’s dimensioners deliver measurements that are certified for trade in just a few seconds. This helps with slotting, and also protects shippers from freight audits as a bonus.

The Final Touches

Before you finalize your slotting plan, you’ll also want to consider the weight and durability of the items you need to slot. Generally, you’ll want to store heavier items lower, and lighter, more fragile items higher up. Obviously, hazardous materials should also be stored away from other items in a designated location.

Warehouses and distribution centers are so diverse in terms of goods stored, size, layout and equipment that there’s no one plan that makes sense for everyone. However, following the guidelines above, even if only in part, can help you greatly improve the efficiency, effectiveness and cost of your operation overall.

For more articles like this, subscribe to our newsletter!

Was this article helpful?

Michael Eichenberg is the co-founder and CEO of FreightSnap, allowing the supply chain, logistics, manufacturing, distribution and transportation industries to measure, weigh, photograph and ID pallets and parcels in just seconds. Learn more and share your ideas on Facebook and LinkedIn.