Shipping and delivery expectations are higher than ever, resulting in busier warehouses, bottlenecked docks, and increased pressure on warehouse workers. Luckily, automated warehouse technology like Dimensioners are becoming increasingly popular and can save time and increase throughput, productivity and accuracy.

Purchasing dimensioning equipment can be a confusing process, and it’s best to consider all your options and unique needs before making a final decision. Our team has installed Dimensioners around the world and created custom solutions for businesses of all sizes, so we’ve answered many questions for those considering new technology. Here are 11 of the most frequently asked questions we get from customers.

What types of Dimensioners are available?

There are two types of Dimensioners: pallet and parcel.

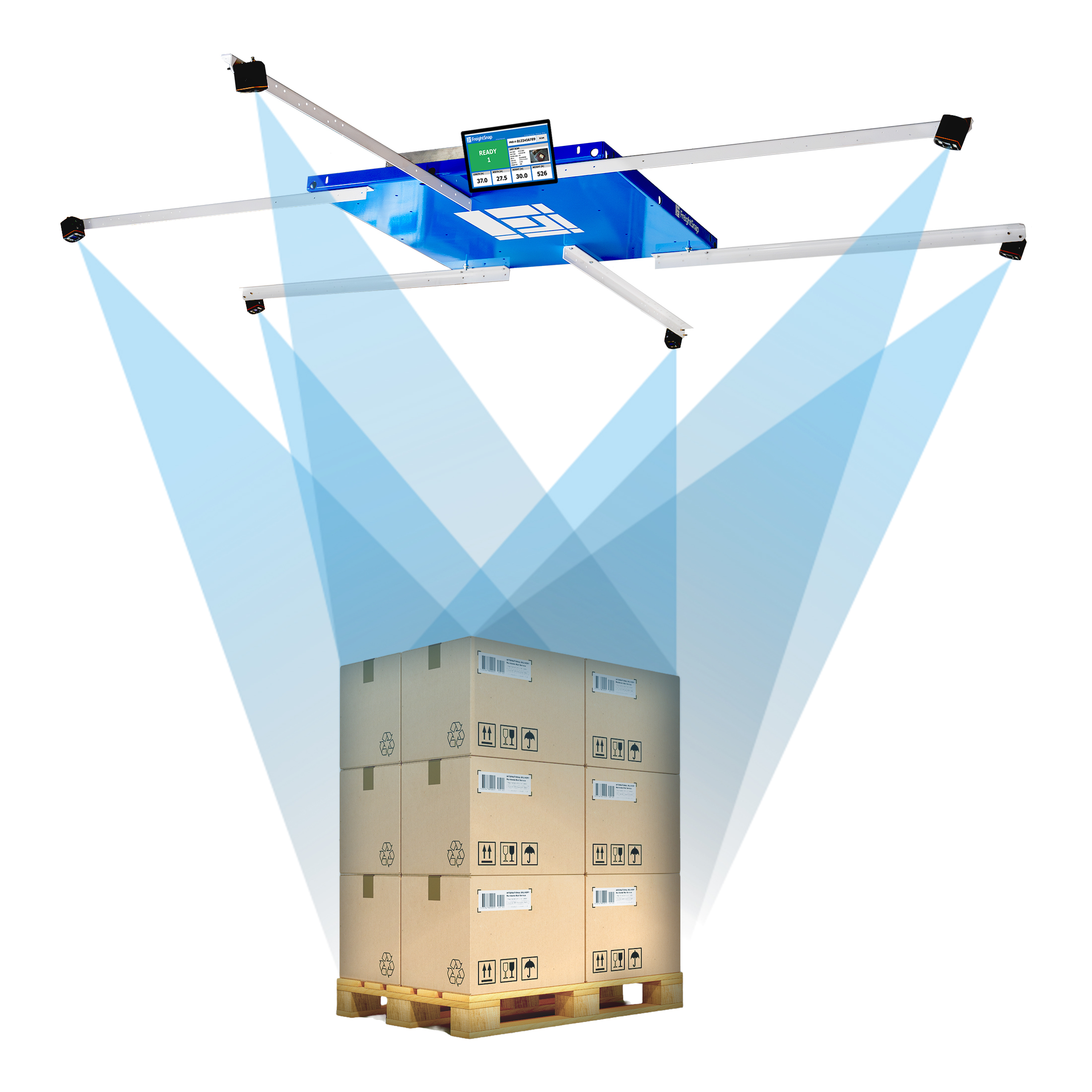

Pallet Dimensioners, as the name suggests, are used to automate the measurement of palletized or larger bulkier freight oftentimes moved with a forklift. They deliver the result in either inches or centimeters which can later be utilized with weight to calculate cubic feet and density for shipments within the United States or Dimensional weight for shipments handled by forwarders and headed overseas.

Parcel Dimensioners are often utilized to measure smaller boxes or objects usually shipped via e-commerce solutions – the same boxes delivered by Amazon, UPS or FedEx. Both types of Dimensioners collect shipment information and can be connected into a WMS, TMS or ERP to streamline the shipping process and store data. Most Dimensioners are capable of producing high-definition images of the freight for identification and damage claim processing applications.

How is a Dimensioner installed?

A Pallet Dimensioner with infrared sensors generally weighs about 80 pounds and can be mounted to the ceiling in your warehouse. Usually, a trained installer will wrap up an implementation in 1-2 days. To adequately see the freight being measured, a Pallet Dimensioner is installed between 12 to 13 feet off the ground utilizing a scissor lift. Heavier Laser-Based Dimensioners take longer to install and may require heavier mounting equipment and bracing to handle the additional weight. It is always best to consult an engineer before mounting any equipment in excess of 100 pounds.

Parcel Dimensioners take less time to install; most products are assembled prior to shipping to your warehouse and require no professional installation. While this is true for most Parcel Dimensioners, there are some that require a technician and onsite assembly.

How much space does a Dimensioner require in a warehouse?

Typically, a stationary Pallet Dimensioner requires about 120 square feet of space, but some can be customized to fit even the tightest areas within terminals. Laser Dimensioners with moving chassis require additional space to accommodate their large frames. Parcel Dimensioners need only about 50 square feet of space.

Are certain locations in a warehouse better than others?

It’s important to utilize every inch of your warehouse, and placing Dimensioners is no exception. To get the best throughput, locate your Dimensioner in an area where you have shipping activity and potentially where freight is staged before it’s loaded, such as an outbound shipping area or parcel packing line.

What’s not included?

Accessories like barcode scanners or handheld computers that help collect cataloging information like order numbers or Bills of Lading aren’t included in the initial cost, although they can be purchased to further streamline your shipping process. Some shipping companies and carriers purchase additional cameras for increased accuracy, as well as computer monitors to view the status of a measurement in more detail. In general, the Dimensioner comes with all the necessary equipment to perform its basic function, and that is to measure your freight. Things like scales and label printers can be added to the Dimensioner but will cost extra. In specialty applications, customers might add more automation with the use of OCR scanners and readers capable of further process improvement.

What types of integration are available?

High-quality Dimensioners provide API software integration to collaborate with your existing warehouse management system (WMS), allowing your team to easily access shipment records and information. While some companies charge an extra fee, others will help you connect your systems for free and will even provide custom solutions to fit your company’s unique needs. Because weight is an integral component in calculating shipping costs, most Dimensioners contain software to integrate directly to all sorts of floor and bench scales.

Is any special lighting required?

While no special lighting is required, placement is key to preventing measurement issues. Certain types of lighting can lead to distorted measurements, so avoid mounting Dimensioners directly under an LED light or in an area with direct sunlight or shadows. Workers wearing highly fluorescent safety vests need to stay outside the measurement area while the equipment is in use.

Do dimensioners need to be calibrated often?

Once placed into service, Dimensioners do not require periodic calibration. Since they are mounted at a fixed height above the floor or a scale, unless they have been damaged or bumped by a forklift or other lift equipment, the initial calibration will not need to be changed.

What type of preventative maintenance is needed?

Dimensioners do not require preventative maintenance. Because they have no moving parts, Static Pallet Dimensioners require no periodic care other than to make sure the equipment is free of debris, which can get in the way of the cameras and sensors. In fact, companies can avoid hiring a third-party maintenance team and save money through ongoing but simple DIY care, like clearing cobwebs. A more sophisticated solution may be required if your Dimensioner has moving parts.

What’s the smallest size a Dimensioner can measure?

Parcel Dimensioners usually measure small boxes, although some can measure a range of items like envelopes, small parts, and tiny electrical pieces in addition to large or oddly-shaped boxes. Each Dimensioner has been tested by an NTEP conformance laboratory, and the certification information for each product is located at https://www.ncwm.com/ntep-certificates. Please check with this database before purchasing any Dimensioning product. If you don’t see it listed, ask the manufacturer to provide a certificate of conformance.

Michael Eichenberg is the co-founder and CEO of FreightSnap, allowing the supply chain, logistics, manufacturing, distribution and transportation industries to measure, weigh, photograph and ID pallets and parcels in just seconds. Learn more and share your ideas on Facebook and LinkedIn.

For more articles like this, subscribe to our newsletter!

Was this article helpful?