What is a Dimensioner?

If you’ve heard the term “dimensioner,” “dimensionalizer” or “pallet dimensioner” tossed around with increasing frequency in the last few years, you’re not alone. These terms and others have been used interchangeably to talk about the equipment that’s being used to reshape the LTL industry in the United States. But what is a dimensioner exactly?

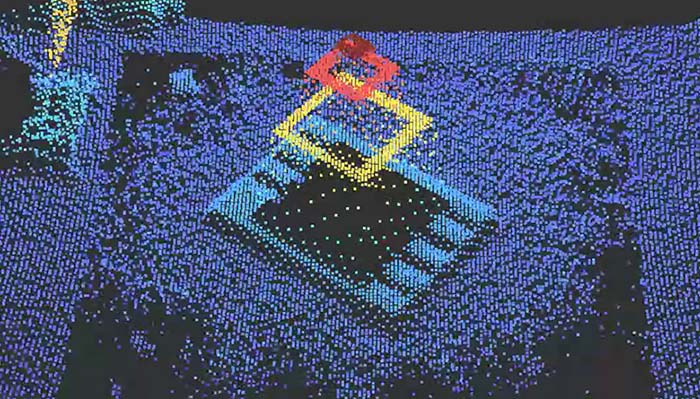

According to Wiktionary, a dimensioner is “a weight and volume measuring device or machine for measuring three-dimensional or cube shaped objects such as packages, parcels, cartons or boxes,” and while that’s certainly a fitting description, there’s plenty more to know.

Wait A Minute – Reshape The LTL Industry?

Over the last few years, LTLs operating in the United States have increasingly moved from a weight and class-based pricing model to a dimensional weight pricing model in an effort to collect revenue based on the space being occupied on their trailers – a model which has been in use globally for years – instead of the total weight hauled.

Prior to the introduction of automatic dimensioning equipment, a pricing model like this would have been impossible to implement given the large number of shipments that pass through carrier cross docks each day. Measuring freight by hand simply wasn’t fast, or accurate enough to keep up.

Today however, dimensioners allow carriers to measure and catalog thousands of shipments daily with pinpoint accuracy.

What This Means For Shippers

Before the wide-spread use of dimensioning equipment, shippers could submit ballpark measurements of their palletized freight with little to no fear of being penalized for inaccuracy, which makes sense; when carriers were forced to measure shipments by hand, only the most egregious measurement errors submitted by shippers were flagged.

With dimensioners in place, however, carriers are paying much closer attention to the accuracy of measurements provided by shippers. As a result, many shippers are seeing an uptick in billing adjustments and freight re-classifications.

How Can Shippers Adapt To These Changes?

Increase the density of freight. Try to eliminate “dead space” in your parcel and palletized shipments, and if possible, reduce the overall size of your freight’s footprint while ensuring that goods are still adequately protected and secured.

Doing so might not have mattered as much before DIM weight pricing, but it assuredly makes a big difference today.

Measure carefully. It seems obvious, but ensuring the accuracy of measurements can save you a lot of time, money and hassle down the road. If you’re a low-volume shipper that dimensions each pallet by hand, measure the maximum length, width and height of your shipments. If you see protrusions on any side, account for them.

If you’re a high-volume shipper, look at purchasing a pallet dimensioner yourself. Many high-volume shippers, 3PLs and forwarders are already using dimensioning technology to ensure accurate measurements and avoid rate adjustments.

Profile your freight. If you haven’t already developed profiles or “templates” of common shipment sizes, consider making it a priority. To do so, record the dimensions and weight of every shipment you send over a specified time period – a few months is usually sufficient. If measuring and recording shipments by hand is too time consuming, a dimensioner can expedite the process exponentially by measuring and cataloging shipments automatically. Some dimensioning companies even offer to import your data into the WMS, TMS or ERP systems you’re already using.

After you’ve collected your data, identify the shipment sizes and weights you frequently used, and if necessary, devise new ways to arrange and pack those shipments for maximum density. Use this information to create your freight profiles. Later, you can send these profiles to carriers for quicker quoting, or even use them to renegotiate rate agreements and volume-based discounts.

Looking Ahead: What The Future Of Dimensioning Holds

Since their adoption worldwide, dimensioner usage has trended up. With more and more U.S. based carriers now joining the fray, dimensioners and dimensional weight pricing appear to be here for the long haul.

If you’d like to learn more about dimensioning, or you’re curious about implementing a parcel dimensioner or pallet dimensioner yourself, we’d love to hear from you. Feel free to contact us at any time.

For more articles like this, subscribe to our newsletter!

Was this article helpful?

Michael Eichenberg is the co-founder and CEO of FreightSnap, allowing the supply chain, logistics, manufacturing, distribution and transportation industries to measure, weigh, photograph and ID pallets and parcels in just seconds. Learn more and share your ideas on Facebook and LinkedIn.