Liquidity Services is a global company that provides surplus management services to its clients. They refer to themselves as “Reverse Logistics” because they help companies by providing a cash market for surplus inventories.

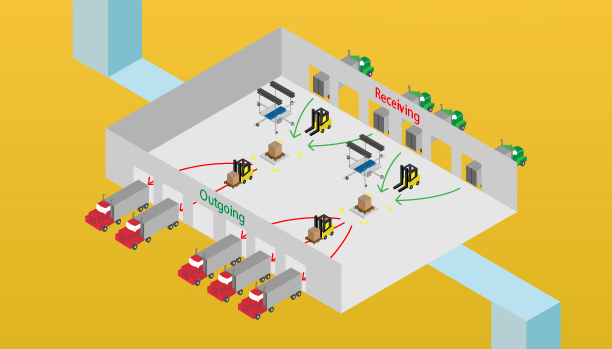

One of the most substantial challenges for the company was handling a massive inflow of inventories. There were many steps to the process. As the pallets of mixed commodity freight arrive, it’s mandatory that the company document the contents of the pallets, the condition of the freight, and the weight and actual dimensions as shipped.

In the beginning, a manual process was put together where employees utilized tape measures, digital cameras, and a custom computer application. On a pallet by pallet basis, the process could take anywhere from two to five minutes per pallet. As the company scaled its operations, the manual process was hampering their ability to grow. It was feared that additional employees would need to be hired, additional space in their distribution centers allocated to the process, and increased cost.

Liquidity began a search for potential vendors who could offer an automated solution. After conducting several vendor meetings, FreightSnap was chosen to provide a scalable solution. FreightSnap recommended the implementation of the FS 5000 pallet dimensioner, FS Parcel Dimensioner, specialized video cameras, and a custom FreightSnap Integration Cloud Portal.

The proposed solution was implemented at four different distribution centers operated by Liquidity Services. The Dimensioners were installed, employees trained, and the solution was implemented in a matter of weeks providing instant productivity gains. The process went from two to five minutes per shipment to a matter of seconds. The FreightSnap cloud provided the perfect platform for integration between the existing systems in place at Liquidity Services with little to no custom programming.

Currently, Liquidity Services is investigating other products from FreightSnap to improve other documenting operations within the process flow. Such as FreightSnap’s “Image Station” which provides a seamless documentation portal and image repository for documenting freight, inventory, and processes.

For more articles like this, subscribe to our newsletter!

Was this article helpful?

Michael Eichenberg is the co-founder and CEO of FreightSnap, allowing the supply chain, logistics, manufacturing, distribution and transportation industries to measure, weigh, photograph and ID pallets and parcels in just seconds. Learn more and share your ideas on Facebook and LinkedIn.